JCB JS200 JRA0214YA KRA1198 152574A1 Forged idler Group/forging idler assembly/China idlers factory/Fabricateed idlers source manufacture

Product Specifications

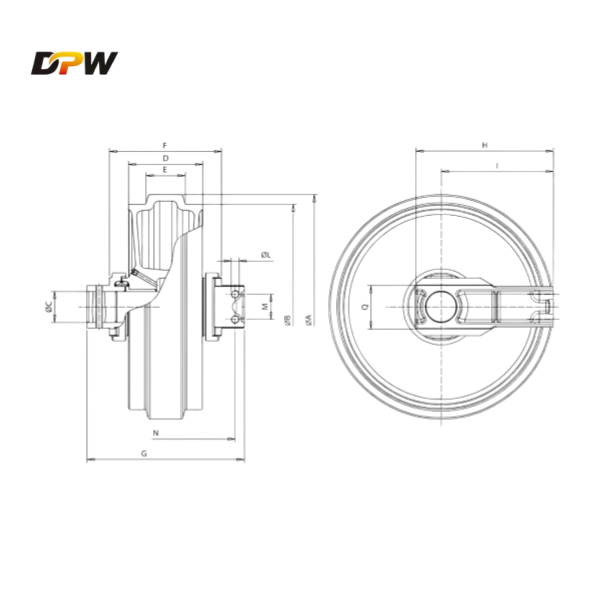

JS200 Forged Idler – Heavy-Duty Track Roller for 20-Ton Class Excavators

JS200 forging idlers are precision-forged undercarriage components designed for 20-30 ton excavators operating in demanding conditions like quarrying, demolition, and hard rock excavation. Built with hot-forged alloy steel, these idlers provide superior durability compared to standard cast rollers.

Excavators JCB JS200 idler GP(P/N|:JRA0214YA;KRA1198;152574A1)forging idler assembly/china idlers factory/idlers manufactur.

Key Features & Benefits

✔ Forged Steel Construction – Higher density and impact resistance than cast idlers

✔ Deep Hardened Surface (HRC 50-55) – Resists abrasion in rocky/gravel environments

✔ Double-Sealed Bearings – Prevents dirt/water ingress, extending service life

✔ OEM Interchangeable – Direct replacement for JS200-compatible excavators

Technical Specifications

| Parameter | Specification |

|---|---|

| Load Capacity | 9,500 kg dynamic load |

| Bearing Type | Heavy-duty tapered roller bearings |

| Flange Design | Double-flange for track guidance |

| Weight | 98 kg (standard) |

| Hardness Depth | 3-5mm induction-hardened |

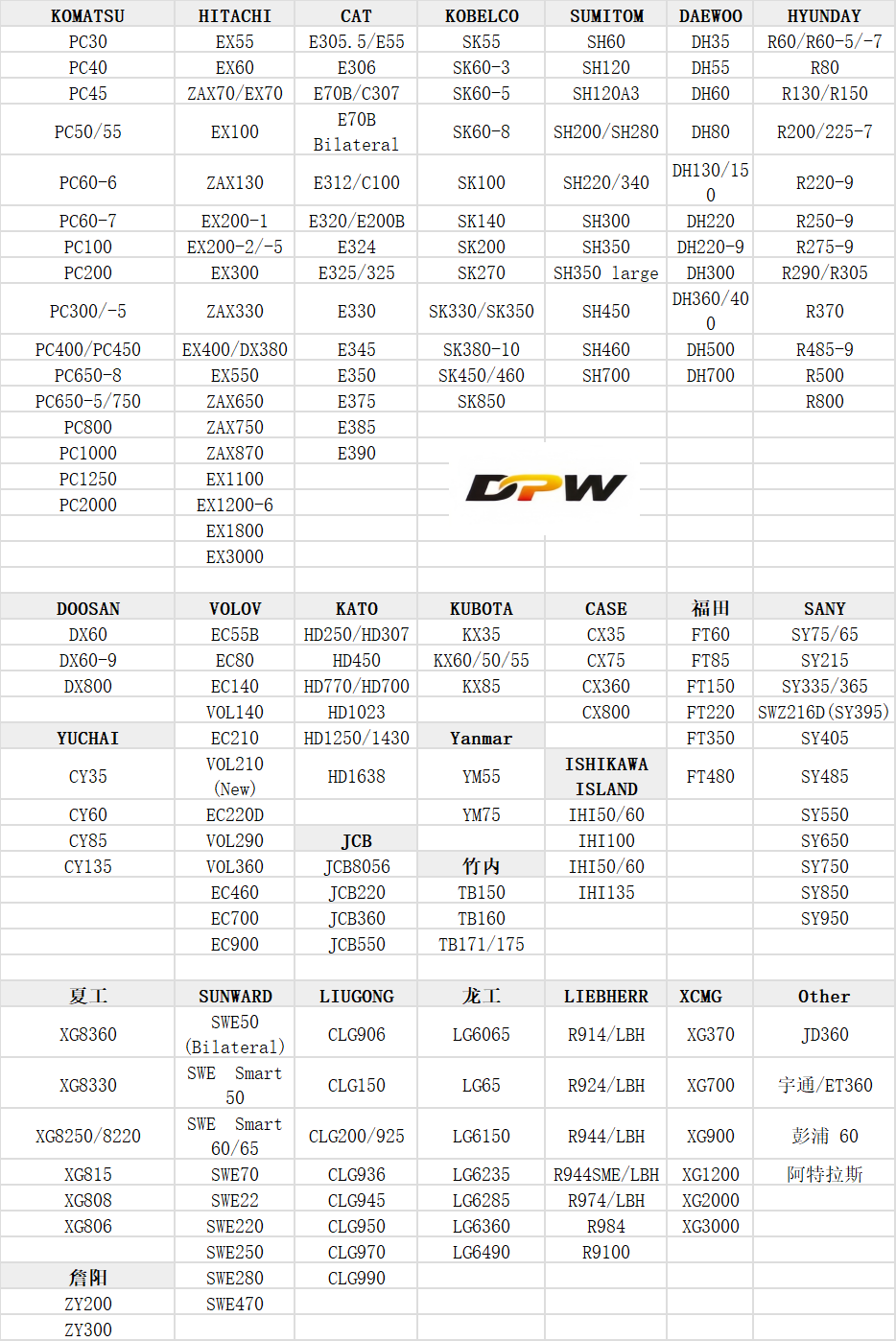

Compatible Machines

JCB JS200/JS220/160/180/190

CX9030

Why Choose Forged Idlers?

✅ 30-50% Longer Lifespan – More resistant to wear and cracking

✅ Better Shock Absorption – Handles impact loads from uneven terrain

✅ Reduced Downtime – Fewer replacements compared to cast idlers

When to Replace?

⚠ Flange wear exceeds 30% of original thickness

⚠ Visible cracks or spalling on the rolling surface

⚠ Bearing play >1.5mm or rough rotation

⚠ Grease leakage from damaged seals

Maintenance Recommendations

Clean regularly – Remove packed mud and debris

Check every 500 hours – Inspect for abnormal wear

Replace in pairs – Ensures balanced track tension

Available Upgrades

Tungsten Carbide Coating – For extreme abrasion resistance

Extended Warranty Options – Up to 12 months coverage

Need a customized solution? Provide:

Machine model & year

Current idler condition (wear measurements if available)

Primary work environment (e.g., rock, demolition, mining)

Also available as part of a complete undercarriage kit (sprockets + track chains + rollers).

For mining or severe-duty applications, ask about our JS200-XD (Extra Duty) forged idlers with reinforced flanges.

DPW-PARTS:thounsands of parts for you to choose from,custmize various chassis parts according to customer needs